|

|

Post by paulg100 on Aug 9, 2016 18:01:57 GMT

OK here is a video of the oscilloscope measuring pots on motors 1 and 6. Yellow is motor 6 which runs great, Blue is motor 1. Measurement readout is monitoring motor 6 (yellow) Hopefully it makes sense. Just to be clear motor 1 IS returning home but there is a very small offset which causes the jitter. tronicgr Thanos does the noise in these signals look acceptable from your experience? (at least before motor 1 jitter kicks in) If anyone has any ideas which might help that would be great. |

|

|

|

Post by paulg100 on Aug 9, 2016 18:07:04 GMT

Some information here copy/pasted from other thread to keep relevant info together

"What I found is that I have at least one motor that is perfect (actually one closest to the control cabinet) providing I leave all others switched off. I can then get a pretty good PID tune and get the motor stopping sharp and returning spot on home consistently without any offset or jitter.

Once I start flicking more VFD's on the loop becomes noisier (signal wise) which is to be expected as your adding more switching noise to the loop.

Once one motor starts jittering, then this contaminates the loop then all hell breaks loose.

Things I have eliminated: Its not a VFD/motor issue as if I run the motors from the VFD panel without the AMC on and no pots then I can run as low as B082 0.01 and everything is buttery smooth ( in an ideal world this is what we should be aiming for, the difference in motion smoothness is very noticeable, even from 0.05 default.)

and I'm pretty sure its not a software config issue. I know you can set pot volt home in BFF software but I have the same issue with other software.

Once I introduce the AMC (even without PC on), the PID loop and the pots then this is when the problem starts. I "THINK" it may be due to noise coming from the pots (signal noise maybe a result of emi from VFD's). This affects their ability to give a proper reading and therefor it upsets the PID loop. Without knowing what is acceptable signal noise its hard to know if this is the issue. I need to take some vids of the oscilloscope in action then we can see and hopefully the guys that are more clued up on electronics can advise.

The otherthing I'm not certain is if not having the pots completely aligned may be causing the issue. The shaft is being pulled off center whilst rotating which affects the reading. (non linear)

I have a 3d printer being delivered in a couple of days which will allow me to print couplers and brackets with CAD accuracy which should get things allgined spot on. At the moment my pots are not spot on. (although close enough that I'm doubtful this may be the issue)

one last thing, I'm using USB cables for my pot signal (originally switched from audio cable). This is pretty thin wire, like 26-28 awg. Maybe there is to much resistance in the wire, but others are using similar cables without issues so I'm not sure this is the culprit."

|

|

|

|

Post by GA-Dawg on Aug 12, 2016 11:53:17 GMT

Hey Paul,

I think your on to something with the pot alignment, and looking back I really should of printed the output shaft to pot connector....It would have been a simpler solution. Here is a quick video I took show the movement I get on two of the motors.

I think I am going to print up a connector and see if that helps.

Cheers

GA-Dawg

|

|

|

|

Post by paulg100 on Aug 12, 2016 12:14:21 GMT

yep that is the same problem ! bit of a relief to know im not alone  Have printer up and running, just designing some couplers and brackets should be good to test this weekend. hopefully with some combined brain cells we can get to the bottom of this. Its my first 3d printer and im loving it  already modded with different bearings and will be adding cooling and support mods at the weekend. was surprised at the print quality even out the box as it wasnt the most $$ model.  |

|

|

|

Post by GA-Dawg on Aug 12, 2016 12:17:41 GMT

If you go back an look at stevant old videos you can see he's got the same issue I just don't think he reported it.

|

|

|

|

Post by GA-Dawg on Aug 12, 2016 12:19:37 GMT

|

|

|

|

Post by paulg100 on Aug 12, 2016 12:21:34 GMT

GA-Dawg If you look at your other VFD's they are still not completely home or there is some interference (or maybe PID is not set right, needs some I gain to kick em to home). The RUN light is still lit, its just that the frequency is below what your B082 cap is set at so they are quite. I was able to get one motor returning home consistently with the RUN light completely OFF when at home. This is ideally how they should be working, but at this point id just be happy to get things quite at 0.05.

|

|

|

|

Post by GA-Dawg on Aug 12, 2016 14:29:50 GMT

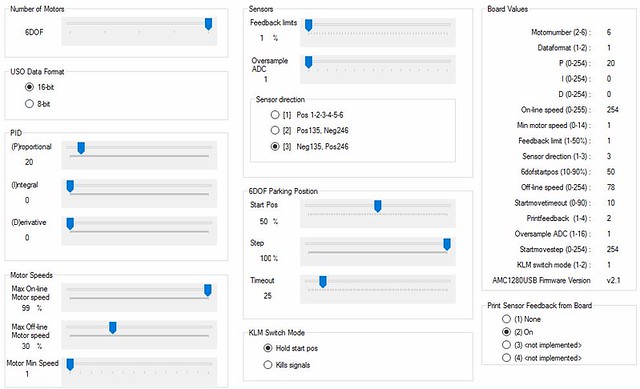

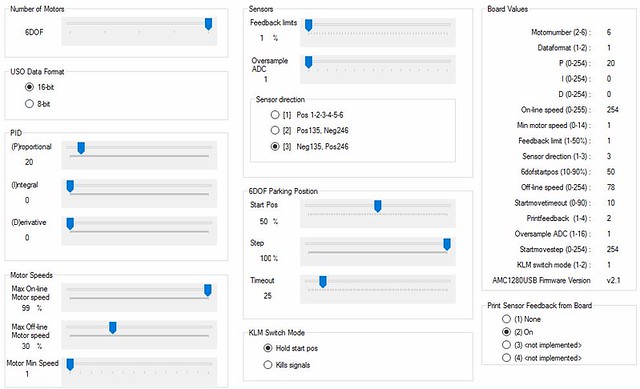

I just went back and reviewed my setup. I forgot that I had started adjusting the PID settings. The video had (P)20 (I)120 and (D)1. I went back and change them to (P)20 (I)0 and (D)0 and all the "run" lights are off except motor 1 and 6. Strange thing is if I increase (I) anything above 10, I get run on 2,3,4,5, and 1 and 6 go silent (Run light goes off). So there might be a bug in the firmware as I thought (I) was a "kick" value so I would have expected all the motors to behave the same way but I really don't understand PID all that well. Here are all my settings.  Cheers GA Dawg |

|

|

|

Post by paulg100 on Aug 12, 2016 15:29:05 GMT

"So there might be a bug in the firmware as I thought (I) was a "kick" value so I would have expected all the motors to behave the same way but I really don't understand PID all that well."

or running 6 motors off the same PID means some motors will be better optimised than others. Having a separate PID for each motor might help but i imagine that brings its own set of problems.

|

|

|

|

Post by paulg100 on Aug 12, 2016 18:04:52 GMT

"If you go back an look at stevant old videos you can see he's got the same issue I just don't think he reported it." I think stevant was/is? running at much slower settings so its more forgiving. As we have found out its fine for monitors but as soon as you put VR in the mix any latency is really noticeable. I can get pretty nice performance with slower dlc and acl, slower max motor speed etc and higher frequency cap, but in VR it feels really off. |

|

|

|

Post by paulg100 on Aug 13, 2016 14:22:42 GMT

First pot coupler coming off the production line  In PLA plus, supposed to be as strong as ABS, certainly prints lovely and seems much stronger than the free PLA filament that came with the printer. |

|

|

|

Post by tronicgr on Aug 13, 2016 14:41:05 GMT

I just went back and reviewed my setup. I forgot that I had started adjusting the PID settings. The video had (P)20 (I)120 and (D)1. I went back and change them to (P)20 (I)0 and (D)0 and all the "run" lights are off except motor 1 and 6. Strange thing is if I increase (I) anything above 10, I get run on 2,3,4,5, and 1 and 6 go silent (Run light goes off). So there might be a bug in the firmware as I thought (I) was a "kick" value so I would have expected all the motors to behave the same way but I really don't understand PID all that well. Here are all my settings.  Cheers GA Dawg Its not really a bug, I just use the same PID initial setting for all motors assuming that the motors are physically the same, but apparently minor differences in the motor coils or gearboxes friction, can have the motors behave a little different. Having separate PID setting for each motor is not hard, but it will be complicated for the small LCD Screen. I'll fix a new firmware that will have an option to use separate PID values or one PID setting for all. Give me a week or two for it please. Later I'll have to ask Fabian to add this separate PID setting in his Fabian Configuration tool, as soon I have the proper commands in place. Thanks Thanos |

|

|

|

Post by tronicgr on Aug 13, 2016 14:50:50 GMT

First pot coupler coming off the production line  In PLA plus, supposed to be as strong as ABS, certainly prints lovely and seems much stronger than the free PLA filament that came with the printer. Hey, I got a duplicator i3 too for small prototypes for my bench at work. I ordered a new extruder head though, so I can print ninjaflex as well. The existing extruder jams the softer materials. flexionextruder.comThanks Thanos |

|

|

|

Post by paulg100 on Aug 13, 2016 16:17:35 GMT

HI Thanos

This is the new plus model, extruder is MK10, think it still has the plastic insert in side though, ill order a microswiss all metal end when I get to it.

its printing great with pla so far.

The flexion extruder looks very nice, something for the future perhaps.

Thanks for taking a look at adding PID for each motor, it will certainly be something interesting to look at and see if it helps optimize our set ups.

Although as you previously mentioned it might cause one drive to work quick/slower than the next, maybe we can compensate for this with the VFD.

|

|

|

|

Post by paulg100 on Sept 3, 2016 9:23:26 GMT

Little update: Added braces to top mounts  New 3D printed pot mounts installed and working great. Will print threaded rod covers and end caps later to finish off.  Bottom frames pretty much done now. Have quote for CNC cut checker plate corner mounts to finish off detailing but not spending any more time/money on detailing until I can get the sim running properly.  tronicgr tronicgr Hi thanos, have you had any time to look at adding PID for each motor yet? Whilst I can get 3-4 motors running well on the same PID theres always 2-3 that wont home properly with the same settings. It feels like they needs slightly different I gain to correct the issue. It feels like I'm chasing my tail at the minute with this so am holding off spending more time on this until we can hopefully get this separate PID option. Thanks.. |

|